CNC Router Plans Roundup

Are you a DIY type and like to build things with your hands? Do you want to have your own CNC router at your home? Perhaps you own a business and want to produce things on a CNC machine but don’t want to invest $6k to $10k for a commercial off-the-shelf machine. Maybe you are just interested in learning more about CNC and want to build a small machine with minimal investment.

If any of this sounds like you, then building your own CNC machine is probably something you’ve considered (or should consider). It can save you a significant amount of money, and enables you to learn the ins and outs of how a CNC machine works. But with all the plans out there, it can be hard to know where to start.

In this article, I have compiled a list of CNC router plans covering a range of sizes and budgets, and have reviewed the top plans in three categories: best low-budget machine, best in performance, and best machine for a large working envelope. These CNC plans are for those who would prefer to build their own machine rather than buy one. Building from a set of plans will save you a considerable amount of money and you will learn the ins and outs of how a CNC machine works.

Let’s start with the list, in alphabetical order.

| Website | CNC Router Model Name | Working Envelope | Plans Cost (USD) | Estimated Cost to Build* (USD) |

|---|---|---|---|---|

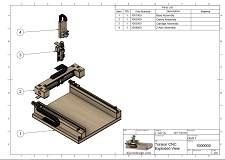

| Dave Gatton | Gatton CNC | 48” x 48” x 6” | $99 | $1000-$1500 |

| DIY CNC Design | Torsion CNC | 37” x 24.6” x 6” | $99 | $2200-$2900 |

| DIY LIL CNC | bigShoulders | 13” x 12” x 4” | Free | $700-$1000 |

| Grunblau Design | MDF3790 | 90" x 37" x 4" | $40 | $1500-$2000 |

| Hobby CNC | Hobby CNC | 30” x 20” x 4” | $10 | $1000-$1500 |

| Joe's CNC | Hybrid and Evo | 48” x 48” x 6” and up | $75 | $3000 and up |

| Kronos Robotics | KRMx02 | 30” x 27” x 6” | $100-$200 | $3500-$4000 |

| Mechmate | Mechmate | 48” x 48” x 6” and up | $100-$200 | $5000 and up |

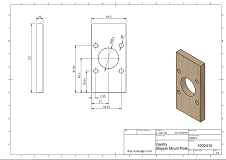

| Momus Design | Momus CNC | 16” x 16” x 5.5” | $20 | $900-$1300 |

*The cost to build these plans-based machines varies widely since there is a lot of latitude for builders to customize and choose their own components. Some websites do not show cost to build and those that do may not include everything necessary to have a fully operational setup. Common items left out of the estimate are the electronics package, router or spindle, wiring, and the computer and software needed to run the machine. I came up with my best estimate of a realistic cost, so take these numbers with a grain of salt.

The plans vary in detail and features, but generally include a parts list, mechanical drawings and instructions that you can follow to make all the parts and assemble them into a fully functioning CNC machine.

That being said, some plans are only the drawings, while others may contain any combination of the following: detailed instructions, pictures, videos of the build process, machine operation instructions, design considerations, sources for parts, and more.

So, which one is best for you? Let’s start by looking at my top picks, then we’ll dig in a little further.

Best for Low Cost:

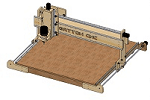

Momus CNC V2.0 www.momuscnc.com/plans.html

If you are looking to learn about CNC or have very limited space, this machine is a good option. The plans are only $20 and the finished machine cost is the second cheapest on this list. The additional expense gets you significantly more performance and double the working envelope compared to the overall lowest cost option. This machine has a small footprint and is fully enclosed so would be a good option for those with very limited space for a machine, or who don’t have a workshop and need to run the machine in a living space.

The Momus plans are extremely detailed and well done with lots of additional information included. Overall, the best set of plans for a limited budget or space.

Best Performance:

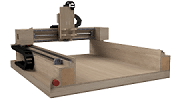

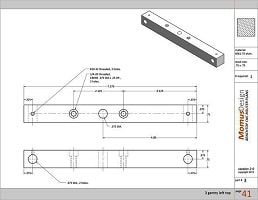

Torsion CNC by www.diycncdesign.com

This machine is where you’ll find best-in-class performance. We’re talking high speed, high accuracy, and low maintenance. The Torsion CNC can be used to make parts quickly by taking aggressive cuts at high speeds. This machine can mill aluminum with ease, unlike many other low cost machines that can take hours just to make small cuts through aluminum.

How? It uses a very rigid frame design and it's the only machine on this list to offer linear profile rails and ball screws. This is the best type of linear motion hardware since it provides extremely high accuracy, even at high speeds, while needing much less maintenance than other designs. In addition, the electronics and drive components have been engineered to allow for rapid speeds of over 1000 inches per minute.

The machine is easy to build for people who have some common woodworking tools. Its size is small enough for most smaller home workshops yet big enough to work on guitars, R/C hobbies, and furniture.

Expect top of the line performance for a total build cost that beats many of the other, lower performing machines on this list.

Best for a Large Working Envelope:

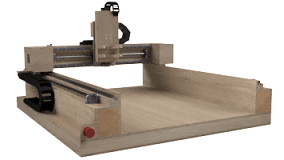

Joe’s CNC Hybrid or Evolution (Evo) www.joescnc.com/joe-s-cnc-shop/

Joe’s CNC has a long history in the DIY CNC router scene. The plans have evolved over time and many improvements have been rolled into the designs over the years. The Hybrid would be a good option for a lower cost build of a 4’ x 4’ size router table. If budget isn’t as much of an issue for you, the Evolution would give you higher performance in that same size category. One nice thing about these plans is that they allow for easy modification to larger sizes such as 4’ x 8’ router tables.

Although Joe's CNC plans are very basic, there is a private forum that you get access to with the plans purchase, which more than makes up for the simple plans. The forum contains a wealth of knowledge and a large, active community to support you in your build and operation of the machine.

CNC Router Plans Comparison

This section is for those of you who like to compare the specifications and differences between each machine and dig into the details before you make a decision.Your budget, size requirements, and performance requirements should help you determine which is the best CNC router for you. I have compiled a lot of the features and specifications of each machine into this comparison table.

| CNC Router | Year Released | Working Envelope | Overall Size | Plans Cost | Cost to Build | Frame Material(s) | Linear Bearing Type | Linear Motion Type | Spindle |

|---|---|---|---|---|---|---|---|---|---|

| Mechmate | 2006 | 48” x 48” x 6” and up | About 72" x 72" | $100-$200 | $5000 and up | Steel | V Bearings on Steel Angle | Rack and Pinion | Router or Spindle/VFD |

| Joe's CNC Hybrid and Evo | 2007 | 48” x 48” x 6” and up | About 72" x 72" | $75 | $3000 and up | Aluminum / MDF | V Bearings on Steel Angle | ACME Screw or Rack and Pinion | Router or Spindle/VFD |

| Gatton CNC | 2014 | 48” x 48” x 6” | About 72" x 72" | $99 | $1300-$1800 | Pine Core Birch Ply | V Bearings on Aluminum Angle | ACME Screw | Router or Spindle/VFD |

| Grunblau MDF3790 | 2010 | 90" x 37" x 4" | About 48" x 100" | $40 | $1500-$2000 | MDF | Ball Bearings on Aluminum Angle | ACME Screw/Rotating Nut | Router or Spindle/VFD |

| DIY CNC Design Torsion CNC | 2018 | 37” x 24.6” x 6” | 53" x 44.5" x 28" | $99 | $2200-$2900 | Baltic Birch Hardwood Core Ply | HIWIN Profile Rails | Ball Screws | Router or Spindle/VFD |

| Kronos Robotics KRMx02 | 2011 | 30” x 27” x 6” | Not Specified | $100-$200 | $3500-$4000 | Aluminum | Ball Bearings on Steel Angle | Rack and Pinion | Router or Spindle/VFD |

| Hobby CNC | 2016 | 30” x 20” x 4” | 36" x 24" x XX" | $10 | $1000-$1500 | Baltic Birch Hardwood Core Ply | Ball Bearings on Aluminum Angle | Threaded Rod | Rotary Tool |

| Momus CNC | 2015 | 16” x 16” x 5.5” | 32.5" x 27.5" x 26" | $20 | $900-$1300 | Pine Ply / Aluminum | ABEC7 Bearings on Steel Flat Bar | ACME Screw Z, Belts X,Y | Trim Router |

| DIYLILCNC bigShoulders | 2011 | 13” x 12” x 4” | Not Specified | Free | $700-$1000 | Pine Ply | Ball Bearings on Aluminum Angle | ACME Screw Z, Belts X,Y | Rotary Tool |

Other CNC Router Plans

I should also mention some plans that you may see mentioned on other websites and let you know why they aren’t on this list. Some years ago, the popular plans were the various Solsylva designs and some of Joe’s CNC’s early designs, the JGRO and Joe’s 2006. The Solsylva website has recently been taken down, so they are no longer available for sale. The JGRO plans can still be found online for free, but aren’t really recommended for other than educating yourself about CNC technology. There is also a set of plans archived on buildyourcnc.com which are no longer promoted since there are much better designs available now. They have been left up as a resource for those who built one in the past.

Still Need Help Deciding?

If you are ready to build a CNC router for yourself but still have questions about which machine would be best for you to build, read our article about how to choose the best CNC Router Plans for you. I am also happy to talk it through with you. Just send an email to [email protected] and we can discuss your specific situation.

Comments?

Are there any plans you know of that I haven’t included here? Would you like to see a more in-depth evaluation of each set of plans? Let me know.